Services

Solutions

Fulltext

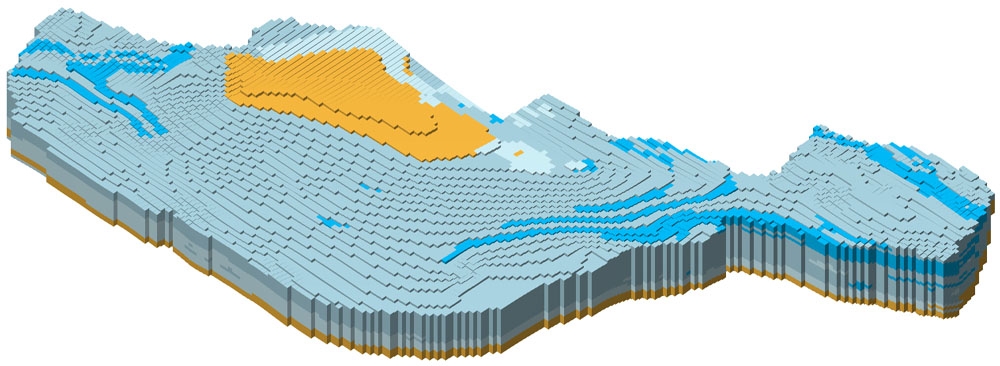

Lithium in the Czech Republic

The G E T s.r.o. Company is actively participating in the evaluation of mineral resources, prospecting and exploration of lithium ore in the Czech Republic. An important result of this activity is to define the new deposits Cínovec-Východ in the Krušné hory/Erzgebirge Mts. and Krásno-Koník in the Slavkovský les Mts.

The development of new technologies in recent decades enforces the demand for a number of raw materials that have been still marginalized. A considerable attention is paid to lithium, which is considered almost a strategic raw material. In the Czech Republic there are significant occurrences of lithium ore, but most of them are poorly explored and requires re-evaluation. The most important deposits are known in the ore districts of Cínovec/Zinnwald and Krásno-Horní Slavkov.

In both of these areas (Krušné Hory and Slavkovský Les Mts.), lithium is bound to the mica minerals of the siderophyllite-polylithionite series, which are known under the general name zinnwaldite.

Zinnwaldite as a lithium ore was exploited in Cínovec already in the middle of the 20th century. Due to the increased interest in lithium as a strategic raw material, a flotation technology was installed in the ore processing in 1958-1960. Procedures used for the production of concentrate were: manual sorting → separation in heavy liquids → foam flotation (Tichý et al. 1968).

About 1,200 tpy of 1.25% Li grade concentrate were initially produced. The production has risen to 4,400 tpy, but since 1962 declined gradually and 1966 was completely stopped. The concentrate was processed into carbonate and other lithium salts in the chemical plant “Spolana” in Kaznějov (Götz and Matějka 1964).

Current world production is based mainly on the lithium bearing brines with a content of about 0.06 to 0.15% Li. Silicate ores spodumene, pollucite and lepidolite are also a source of rubidium and caesium, most are they directly used in advanced ceramic and glass technologies (Starý et al. 2010). Lithium minerals serve as a flux in the production of fire-resistant glass and emails. Use of zinnwaldite in ceramics and glass industry is excluded for high iron content (around 12%). However, the iron in the crystalline lattice contributes significantly to very good results during processing by magnetic separation (Botula et al. 2005). Production of lithium carbonate, the basic marketable product, from the mica concentrate is an attractive alternative for the time being mastered at experimental level. The zinnwaldite concentrate could be treated by calcination with calcium sulphate and hydroxide under elevated pressure and temperatures around 350 °C. The product is then leached by hot water and the obtained extract is subjected to crystallization. This methodology is less energy demanding than the melting with sodium sulphate and excludes escapes of toxic fluorine. Simultaneously, all the iron goes into insoluble compounds and thus get into the extract.